Process mining is an invaluable methodology for data-driven process excellence. By automatically discovering real processes from event log data, process mining provides powerful fact-based insights to understand and optimize operational processes.

As a data analyst with over 10 years of experience in analytics and process optimization, I‘ve witnessed firsthand the transformative impact of process mining. That‘s why it‘s no surprise that 93% of business leaders aim to implement process mining, according toAimultiple. However, the same survey found that 79% of leaders have yet to actually adopt process mining, with 52% citing lack of expertise as a barrier.

Drawing from my own expertise, I‘ve outlined the 5 essential steps for a successful process mining implementation. Follow this comprehensive guide to achieve measurable process improvements in 2024.

Step 1: Plan Your Process Mining Project

Careful planning is crucial to maximize the value of process mining and avoid common pitfalls.

Define Your Process Scope

Resist the urge to analyze your entire process landscape at once. It‘s best to start with 1-2 priority processes where process mining can deliver quick wins.

For example, accounts payable and claims processing are common early targets for process mining. Focusing on fast-moving transactional processes allows you to more rapidly achieve ROI.

Assemble Your Process Mining Team

Process mining combines analytical, technical and process expertise. Your team should include:

- Process analysts to scope analysis and recommend improvements

- Data engineers to extract, transform and prepare event log data

- IT staff to facilitate data access and manage tool deployment

- Process owners to provide context and validate analysis

For a manufacturing company, this could mean your business analysts, data warehousing team, IT application managers, and production managers.

Map Out Roles and Responsibilities

Clarify responsibilities across the project lifecycle:

- Data engineers handle data extraction, cleansing, and preparation

- Analysts focus on discovery, analysis, and sharing insights

- IT provides implementation support and manages access

- Process owners give context and feedback into analysis

This avoids confusion and keeps all contributors aligned.

Create a Detailed Project Plan

Define key milestones across data preparation, discovery, analysis, recommendations, and conformance checking. A phased agile approach allows for iterative delivery and fast feedback.

Realistically, an initial process mining project can take 8-12 weeks for thorough, high-quality analysis. However, focus on demonstrating value quickly to build momentum in the organization.

Step 2: Prepare Your Data

Robust process analysis requires high quality event log data. Plan for the 80% of effort that data preparation entails.

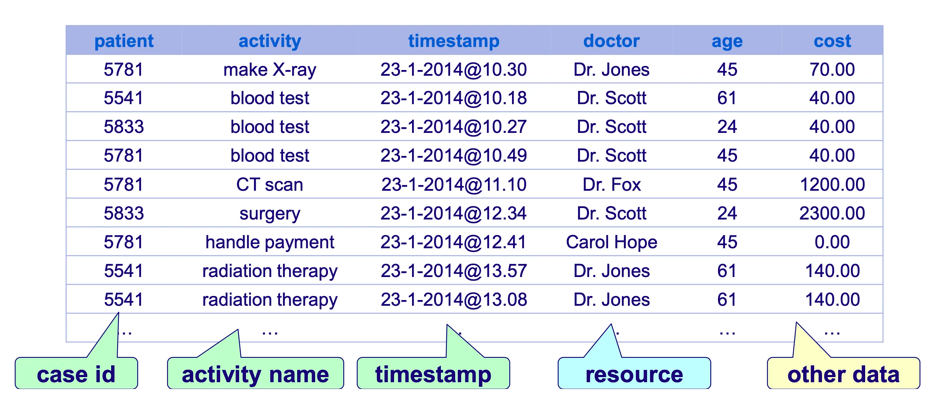

Understand Event Log Requirements

Process mining analyzes event logs – records of process steps as they are executed. Logs must include:

- Case ID – Unique identifier for a process instance

- Timestamp – Date and time of event

- Activity – Step or task name

- Resources – People/systems involved

- Other attributes – Cost, approvals, outcomes etc.

Identify Your Data Sources

Source systems like ERP, CRM, or BPM systems track process execution. You may need to consolidate data from several systems to cover end-to-end processes.

Extract and Transform the Data

Leverage your ETL process to:

- Pull event data from sources into a staging area

- Resolve inconsistencies through cleansing

- Consolidate disparate datasets

- Structure data for process mining tools

This step requires close collaboration between data engineers and process analysts.

Assess and Improve Data Quality

Verify that data is:

- Complete: No critical gaps in event data

- Accurate: Times and activities reflect reality

- Consistent: Case IDs and attributes are stable

Target 95%+ data quality for reliable insights.

Anonymize Sensitive Data

Remove or mask any personally identifiable information while preserving analytical value.

Format Logs for Ingestion

Structure data into the proper case ID, timestamp, activity format for process mining tools. Test with sample logs.

Thorough data preparation is the foundation for impactful process discovery and analysis.

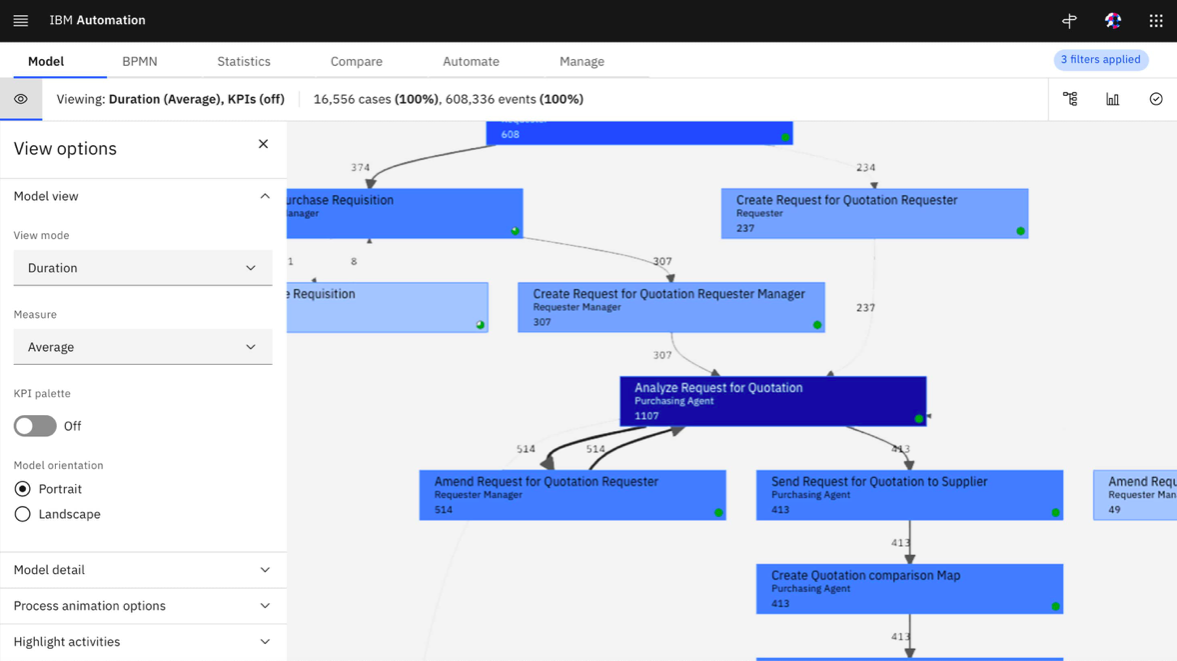

Step 3: Discover and Visualize Processes

Once data is prepared, process mining algorithms will reconstruct real process flows for analysis.

Run Automated Process Discovery

Process mining algorithms accurately model the end-to-end process flow from event logs, visualizing the actual processes.

Even the most complex real-world processes with extensive variations and decisions logic are discovered with 100% precision.

Visualize Processes for Insights

The discovered process map is an interactive visualization encompassing every case, step, and decision from the source data.

Process owners can validate that the visualization matches reality to build trust.

Filter and Drill-Down On Demand

Dynamically filter the process map by time period, outcomes, case attributes, or paths to analyze specific process behaviors. Smooth drill-down reveals underlying process complexity.

Identify Deviations for Further Analysis

Visual inspection often reveals deviations like bottlenecks, exceptions, missing activities or unnecessary steps. This speeds root cause analysis.

The visualized process maps enable process teams to explore their processes hands-on. This drives engagement, learning and ideas for improvement.

Powerful process visualization turns raw event data into irrefutable process intelligence. Now the real analysis begins.

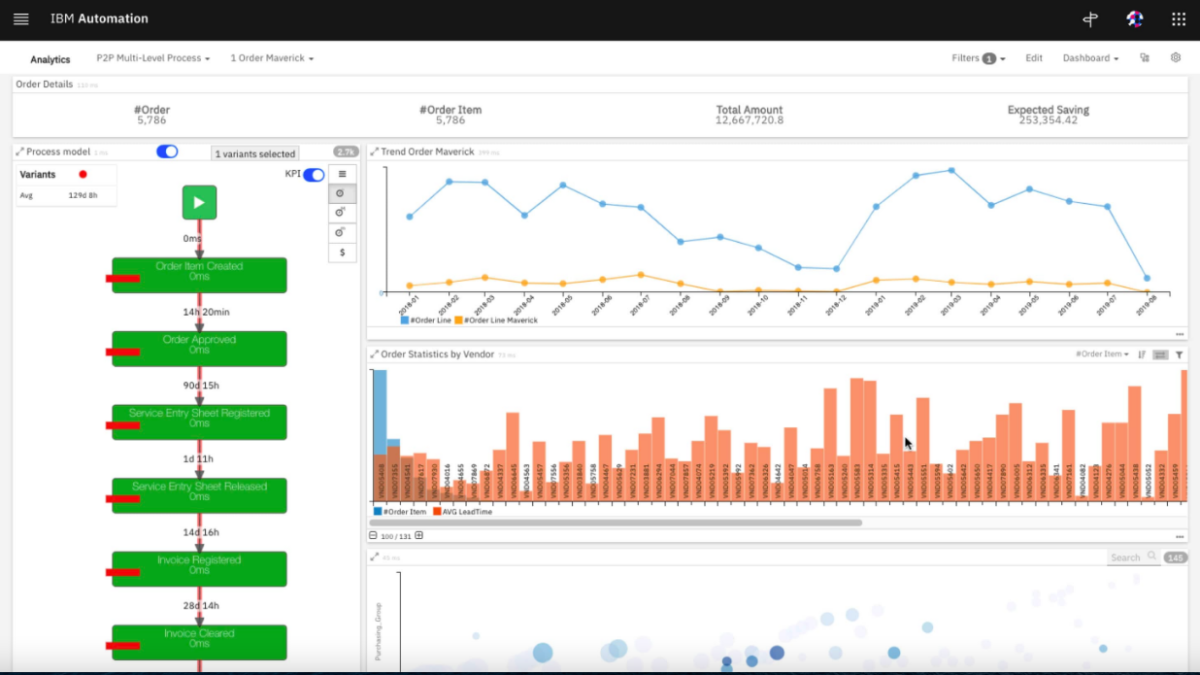

Step 4: Analyze Process Performance

With end-to-end processes visualized, we can measure performance to identify issues and improvement opportunities.

Calculate Your Process KPIs

Built-in dashboards automatically calculate process metrics like case volume, cycle times, throughput, wait times, and more. Tailor measurements to your specific process KPIs.

Identify Performance Bottlenecks

Interactive analysis makes it easy to filter and drill-down into the visual process map to pinpoint steps with excessive time, quality issues, or other bottlenecks.

Conduct Data-Driven Root Cause Analysis

The tool associates problems like delays to potential root causes, like staff overload, manual handoffs, or lack of standardization. This accelerates solving the right issues.

Recognize Automation Opportunities

Automating manual activities or applying predictive analytics to guide decisions can dramatically boost efficiency, quality, and consistency.

Build Consensus for Change

Share fact-based analysis with stakeholders to align on problems and opportunities. This drives buy-in for process changes.

Armed with irrefutable process insights, we can now confidently define an optimization roadmap.

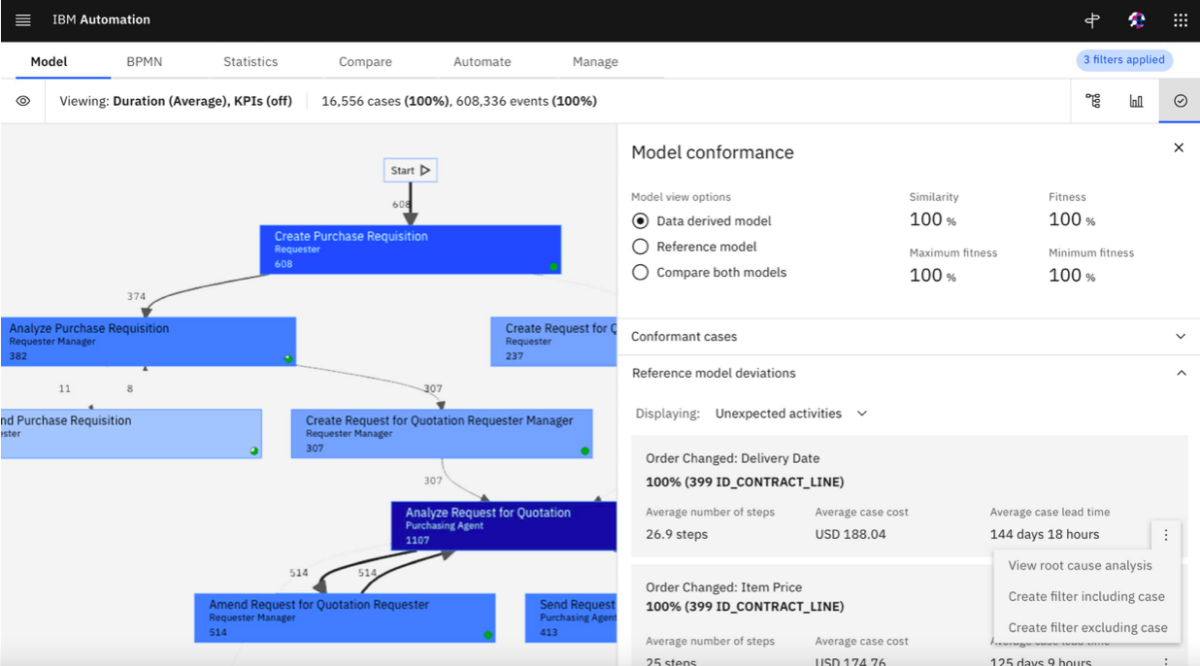

Step 5: Validate Improvements with Conformance Checking

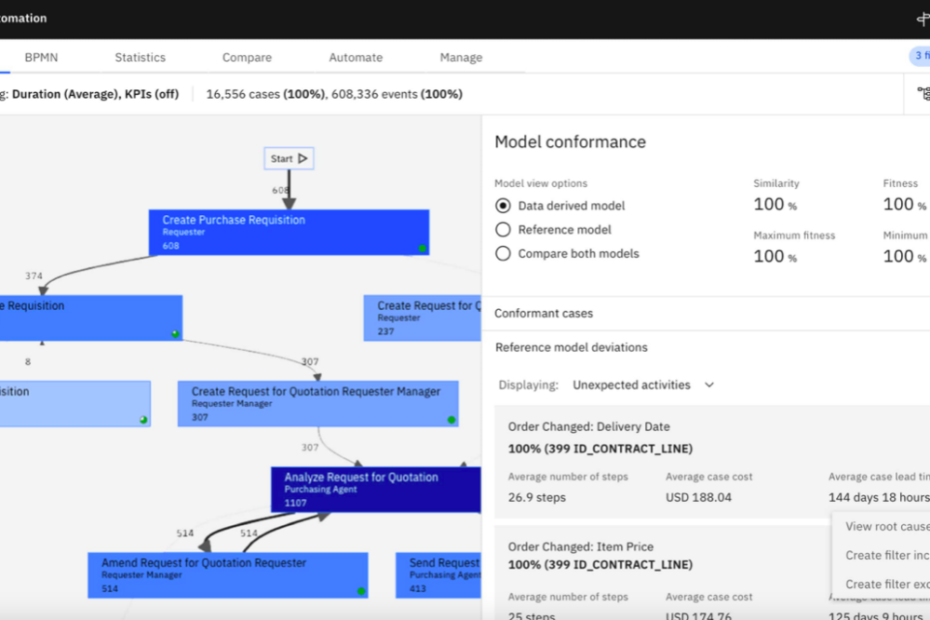

The final step is using conformance checking to validate process changes against the target process model.

Define the Target Process

Redesign the "to-be" process workflow to incorporate improvements identified through analysis, such as new automation tools, policies, or routing.

Upload the Target Process Model

Bring the documented target process model into the process mining tool. BPMN models can typically be imported directly.

Continuously Measure Conformance

The process mining tool compares event logs to the target model to calculate the conformance score and identify deviations.

Monitor Conformance Over Time

Check conformance at regular intervals as changes roll out. Rising conformance confirms process improvements are taking hold.

Incorporate Stakeholder Feedback

Discuss conformance results with process teams to uncover any additional changes needed to optimize adoption and outcomes.

Conformance provides the tangible evidence that process mining is delivering measurable improvements.

Accelerate Process Results with Process Mining

By following these 5 steps, organizations can tap into the tremendous power of process mining to achieve significant process improvements during 2023.

While developing in-house expertise takes time, getting started with process mining is faster and easier than ever:

-

Learn hands-on with free process mining tools like Celonis EMS, UiPath Process Mining, etc.

-

See demos of process mining in action across industries via online interactive demonstrations.

-

Access training resources like the Process Mining for Dummies guide.

-

Get expert help from process mining consultants who can accelerate your implementation and results.

Follow these proven steps to finally translate process insights into impact. Let 2023 be the year you transform operational excellence with the power of process mining.